Canadian ROV Manufacturers

I have been travelling around British Columbia in Canada over the past month looking at the potential for emigrating there. Aside from exploring one of the most spectacular regions on the planet there were two things I wanted to get out of the trip; would I like it there, and were there any employers interested in taking me on – after all that is part of the process for someone like me to get over there.

Initially I had in mind to investigate whether running something like a Techshop or Makerspace would be a self sustaining business in some of the smaller centres. Prior to heading over to Canada I had been in contact with Innovation Island, a small tech-startup accelerator organisation based in Nanaimo on Vancouver Island. I reasoned they would have the best handle on what was viable and what was not. This earlier conversation had pretty much indicated that Techshops and Makerspaces were not a viable standalone business at this time and would have to be supported by another bigger organisation such as a local council, or educational institute. This is more or less the same as the situation here in New Zealand. The conversation finished with the words “If you get across to Vancouver Island, come in a see us.” Seeing as I was in Vancouver for a period I took a couple of days to go over to Nanaimo.

It was a hard job actually finding someone to talk to. While trying to arrange some time to meet with someone from Innovation Island, I spoke with Kelsey Wolff, the Community Manager for SquareOne, a startup incubator space with links to Innovation Island. One of her comments really caught my attention and made me think about how small high tech businesses can be sustained in smaller centres. Her observation was that the small high tech startups based in the smaller centres struggled to find talent in the local population and so in order to grow they needed to move into the larger centres such as Vancouver. This of course had implications for what I was thinking about at the time which was developing Techshops and Makerspaces in order to grow those talent pools.

I finally managed to get five minutes to talk with the Executive Director of Innovtion Island, Paris Gaudet. Within that five minutes the discussion got onto ROVs and I found out that there was an ROV manufacturer based in Nanaimo. As soon as I got back to my hotel I arrange a time to go out to their workshops the next morning.

Seamor Marine

The company was Seamor Marine Ltd. who design and manufacture small inspection type ROVs. Operations Manager, Roy Coles met with me and showed me around their facilities. It was fascinating to see a number of ROVs around of different sizes, different levels of assembly, and in the case of those returned for some refurbishment, different levels of use/abuse. It looks like they can certainly take the knocks.

Roy Coles with the most sophisticated coffee maker in the world. (Photo from Seamor Marine Facebook Page)

In addition to the ROV’s Roy showed me one of the 7-axis manipulator arms that they can add to their ROVs and also some of the testing equipment. For testing the ROVs they have a large tank in which they have enough room for an ROV to drive around a little. Every component and assembly they install on their ROVs is also tested to the rated depth, which is up to 1000m in some cases. To do this they had a small steel chamber that could be filled with water and pressurised to simulate the appropriate depth. What amused me about this was that it was very similar to the test chamber arrangement I had been struggling with to test the cable glands on my system. The difference was in the size and the materials used.

Seamor Marine 300F2/4 ROV (Photo from Seamor Marine Website)

Also of interest was that the ROVs were not neutrally buoyant. If things go wrong, the ROV will float up and be able to be recovered. This means that there is vertical thrust happening at all times to keep it submerged. The buoyancy was provided by a flotation pod made from a foam material and mounted on top of the ROV. With such a high centre of buoyancy there is no need for fancy control to counteract the off-centre weight of a manipulator when it is in use. The ROV will naturally remain upright despite the reaching and movement of the manipulator.

Seamor Marine ROVs - With and without manipulator packages. (Photo from Seamor Marine Website)

Seamor Marine employs 12 staff who do the designing and assembly. Component manufacture mostly happens in other manufacturing shops around the local area. Being a small organisation it would have been extra-ordinary lucky on my part for there to have been an opportunity there for me at the time. It was great to meet up with them and learn about the how the real ROV manufacturers work and see their toys. As I headed off Roy suggested I get in touch with International Submarine Engineering Ltd who were based in Port Coquitlam which is part of the greater Vancouver metropolis.

Incidentally I saw on the Seamor Marine website that they had just sold one of their ROVs to a Tourist operator based in Fiordland down the bottom end of New Zealand’s South Island.

International Submarine Engineering

Because of time constraints, I was unable to arrange a time to visit International Submarine Engineering (ISE) so I decided to chance getting turned away by the receptionist and would just turn up on their doorstep in the hope of meeting someone.

An ISE HYSUB 40 ROV (Photo from the ISE Website)

Using a metro system day pass, a metro system network map, and some tiny slithers of Google maps which were all that I could capture on my little old EEEPC I managed to get myself out to Port Coquitlam and to the doorstep of ISE.

The receptionist hadn’t quite managed to kick me back out when a guy turned up and agreed to show me around. He was the founder and President of ISE, Dr James McFarlane, and was expecting a group of Engineering Students from one of the Universities to turn up at any time.

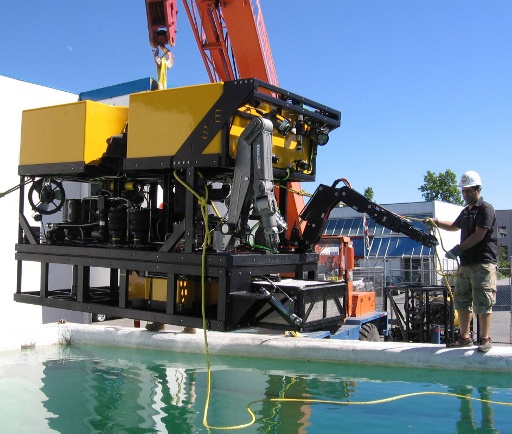

The latest bath toy from ISE. It sure beats the rubber ducky. (Photo from web)

ISE is a different scale from anything I had seen before. Their ROVs were large, the size of a van, and rated to extraordinary depths and very long missions. In addition to the ROVs they also designed and manufactured a range of autonomous underwater vehicles (AUVs) which were shaped a bit like large yellow torpedoes (Well actually having never seen a real torpedo I don’t know how big they are in comparison.) These are used under the ice of the North Pole to map out the sea floor and carry out other surveillance tasks. The capabilities are extraordinary with depth ratings of 5000m and working ranges of up to 450km.

AUVs being assembled in the ISE workshops. (Photo from ISE Website)

A number of their systems are also for the military.

Again it was interesting to see what they were working on and the range of undersea vehicles that they had designed. Prior to meeting them I had not been aware of autonomous underwater vehicles nor the how semi-submersible remote and automous vehicles would be useful.

Despite the large size of their devices, ISE are not a large organisation, and so again, I would have had to have amazing luck to find an available opportunity there.

Final Comments

Having not known that there were ROV manufacturers in Canada, let alone in the areas I would be passing through I was very pleased to have the opportunity to visit these companies, meet some of the movers and shakers, and get to see the toys they were developing.

How much do the various ROVs I saw cost? I have no idea, it was not something I was prepared to ask. I can guess that they would be a pretty penny.

Seamor Marine originated with a project by the high tech robotics company Inuktun and as I understand it, the principal developer was originally from ISE. Innovation Island had been supporting the development in some way. It appeared to me that there is a little more support for innovation in British Columbia than there is in New Zealand, and the presence of larger established manufacturers helps ensure that the necessary “seed” knowledge and expertise is present.

Incidentally I tried to contact someone at Inuktun to arrange a meeting while I was in Nanaimo but could not get past the receptionist.

Photos on this page were shamelessly copied from the manufacturers’ websites, and other web sources.